FROM A PASSION FOR PADDLING WORLD-CLASS WHITEWATER GREW THE DESIRE TO MAKE THE BEST DAMN BOATS POSSIBLE. ELEVEN WHITEWATER ENTREPRENEURS SHARE THEIR HOPES, DREAMS, FAILURES, AND WHAT IT’S LIKE TRYING TO MAKE IT AS AN INDEPENDENT KAYAK MANUFACTURER.

WAKA KAYAKS

SAM SUTTON AND KENNY MUTTON

THE SUN IS BARELY UP. Soft light touches the green water of the Kaituna River, making it sparkle. Giant fern trees, straight out of Jurassic Park, hang over the river as boat shaper Kenny Mutton and decorated freestyle athlete Sam Sutton slide from the riverbank into the water. Mutton and Sutton let whitewater take the sleep out of their eyes as they start their daily 6:30 a.m. lap of a river that is their backyard. If the roar of whitewater didn’t drown out their voices, a terrestrial bystander might know this isn’t just a leisurely paddle. It’s also a business meeting.

Good friends, good connections and good timing led to the creation of Waka Kayaks in 2013. Back then, Mutton and Sutton were discussing the idea of buying the Tuna mold from Bliss-Stick Kayaks and starting their own production.

“Both of us were a little out of money,” says Sutton. “I had enough to buy the mold, and Kenny paid for the set-up costs and airfreighting the mold. We both went in halves.” Mutton was the shaper of the original Bliss-Stick Tuna and Sutton helped with design and testing so it felt right that they were reunited with the design.

“Waka means canoe in Maori,” says Sutton. “We wanted to keep our Kiwi roots even though we weren’t going to manufacture the boats in New Zealand.”

Designed and tested on the warm water of the Kaituna, Waka’s rotomolded boats were manufactured for three years in the cold north of the Czech Republic. The two paddlers had contacts in the Czech making the start-up easier and knew it was close to their largest market, which meant saving money on shipping costs.

At that rural Czech factory, the building was camouflaged with no signs for Waka Kayaks out front. The houses butted up against each other along the street, giving way to a massive roller-style garage door that opened up into what used to be an old pig farm.

In May 2016, the factory moved to Italy, 40 kilometers south of Milan. “We had a bit of a supply issue at the old location when it came to production—the move has been an awesome step forward for Waka and its future,” says Sutton. “Plus, the food is really great in Italy.”

“We have only just figured out how much running a business costs, and it’s more in buying materials for full-scale production. Some things you need to buy three years supply,” says Sutton. “That makes a big impact on balancing cash and at the end of the day you are still unsure you will get a single dollar from the year.”

Using a third party for manufacturing means Mutton and Sutton have less control of production times and supply. The biggest challenge Waka has faced is keeping up with the demand of boats, says Sutton. “People knew who I was in Europe and Kenny was the man at shaping so it was easy to market the boat straight away,” he says.

When Sutton is paddling and racing around the world, it’s satisfying for him to turn up at a river and see a fleet of Wakas at the put-in. It’s even more rewarding when he hears that his boats help paddlers progress their ability. He talks about a 50-year-old Tutea paddler who fired up a run she’d only done once in her life. “She said it took her a grade above her previous ability,” says Sutton. “Giving her the chance to paddle harder whitewater again was cool.”

A handful of professional kayakers, including Aniol Serrasolses and Evan Garcia, have turned down money from other companies to paddle for Waka for free, says Sutton. “As soon as they tried it, they didn’t want to paddle anything else,” he adds. “We just want to make a boat that we love racing down in the morning and that makes you feel like a gangsta.” —Carmen Kuntz

FEATHERWEIGHT KAYAKS

BEN FRASER

IF THE HAND-DRAWN, custom art decorating the bottom of the boat doesn’t give away a FeatherWeight kayak, the amount of air between the boat and the water will. The kayaks are designed, built and tested in the Ottawa Valley, where owner Ben Fraser often takes his lunch break at Buseater. When the bright blue Marlin on the bottom of his boat is visible, it means his session is going well.

FeatherWeight’s origin story is simple. “Basically, it’s just a couple dudes who love to kayak. We wanted our own boats to be the best they could be and people liked them. There was demand so we started making them,” says Fraser.

Ottawa Valley local and freestyle authority, Dave Nieuwenhuis, and Fraser worked side by side to combine the characteristics they liked from different boats. “I missed the edges from my O-Fish but loved the forgiving rides of the Superstar,” Fraser says. The two paddlers created a Frankenstein prototype that had the whole package. Nieuwenhuis is no longer a part of the handson production but is still the creative genius behind the brand’s hand-drawn artwork.

FeatherWeight boats currently come out of an unlikely location: a small, 10by 10-foot shop in an ordinary south Ottawa neighborhood. The long hallway leading into the workspace is lined with molds piled up along the wall. A single workstation occupies the center of the room and boats, molds and materials lean against the walls and sit stacked in corners. Past workshop locations have included garages and the Nieuwenhuis family barn near the Ottawa River, but this suburban shop is much warmer during Canadian winters.

Fraser has always been self-employed, so the transition from carpentry to boat builder was a fluid one. “It wasn’t so much a one-time investment as a cumulative investment and putting in lots and lots of time,” say Fraser, who now works fulltime on boats. Fraser takes home money for the labor of each kayak but admits it’s sometimes a struggle to finance large purchases like rolls of carbon fiber cloth.

“When I can afford to build another mold I do,” he says. “I’ve managed to feed myself and keep a roof over my head. It’s starting to feel quite successful.”

Despite FeatherWeight’s growing popularity, each boat is built with impeccable attention to detail. Six FeatherWeight boats were flying high on Garborator during the Freestyle World Championships in 2015.

Materials and design are key to FeatherWeight performance. “I think both the construction—aerospace grade carbon with premium epoxy—as well as the design of the boat itself, sets us apart,” he says. “And, of course, the custom artwork.” A fully outfitted FeatherWeight goes for $3,200 CAD. Over the last year FeatherWeight has sold 30 boats.

Fraser compares paddling a carbon boat to riding a top-of-the-line mountain N bike. The all-round performance translates to a better experience. It’s easier to catch the wave, and easier to get a good bounce, which translates to easier airtime because you have a lighter boat over your head.

Positive feedback from paddlers fuels Fraser during those long days and

nights in the shop. He loves seeing others having great surfs and epic days on the water. “For me, the most rewarding part is seeing so many people having their best boating days ever.” —Carmen Kuntz

SPADE KAYAKS

HANS MAYER, OLLI GRAU, MATZE BRUSTMANN, JAN HALUSZKA AND JENS KLATT

WHILE SPADE KAYAKS may be new to the game, the guys behind it are not. Together they have over a century of experience. The German and Austrian company was created from a lifelong passion and dedication to whitewater kayaking.

Founder and CEO Hans Mayer is a long-time innovator of the European kayak market; he worked with Prijon in the ‘90s, ran a kayak shop for over a decade and was a European distributor for Confluence. He always dreamed of owning a kayak company, so when he realized most kayaks weighed over 55 pounds and thought they satisfied profit margins more than paddlers, he decided something needed to be done.

The idea percolated for a while and in 2014 all those years in the industry paid off. Knowing all the right people, he was able to assemble his dream team: Matze Brustmann, renowned whitewater kayaker and extreme skier, came on board as a product tester. Jan Haluszka contributed his 3-D modeling skills. Jens Klatt became the company’s graphic designer and photographer. And the founder of Eskimo Kayaks, Edi Schnappinger, is advising.

Mayer knew that much of his kayak company’s success would come from its designer so he enlisted one of the best. Designer Olli Grau was a freestyle champion in 1995 and literally wrote the book on the sport, White Water Kayaking: The New School of Modern White Water Kayaking. He has worked with other boat manufacturers in the past, creating such classics as the Dagger RPM and the Necky Blunt. Grau’s focus is as much on ergonomics and weight optimization as it is on creating a boat that can handle the rigors of aggressive paddling.

To improve performance and reduce weight, Spade opted to use blow molding to manufacture their kayaks. According to Spade this creates a much denser and significantly stiffer hull while reducing the overall weight of the model by 10 percent when compared with a similarly sized rotomolded hull.

The only boat in Spade Kayaks’ lineup so far is the Ace, also known as the Ace of Spades (see our review on page 51). Grau and the rest of the Spade team created a sturdy cockpit featuring a direct interface between paddler and hull. The footrest, thigh braces, seat, hip pads and backrest are tailored to the ergonomics of a paddler. The design team consulted orthopaedists to ensure the seat directly connects the paddler to the boat in a way that isn’t tiring, cramped or forced.

“Everybody in the company is a paddler at heart,” confirms Jens Klatt—at the end of the day, they just want to make the best boats possible.

With no external investors, Spade Kayaks is entirely funded privately, which means this quintet can do whatever they like so long as they keep their customers happy. And so far so good—Spade has manufactured, and sold out, approximately 500 kayaks to date. For now, distribution remains primarily in Europe.

“Since our investment in the molds was so immense—blow molding is expensive!—all of us are working for free at the moment,” says Klatt. “That means we need other jobs to make a living. Therefore, the time we can spend in Spade is limited and it could be dangerous for us to grow too fast.”

So, what will the future bring for Spade?

“Good question,” says Klatt. “Slow growth with a close focus on quality is our motto at the moment. But we will keep on trying to reduce every gram we can without losing stiffness and safety features.” —Colin Field

ED SKRZYPKOWSKI

WHEN IT COMES TO squirt boats, surf kayaks and freestyle kayaks, you wouldn’t exactly call Binbrook, Ontario, the world epicenter of the sport. But just 27 minutes from steel-town Hamilton, resides Murky Water Kayaks; a place many of the world’s best paddlers look to when they need a custom boat.

Owner Ed Skrzypkowski is the shaper, builder, marketer and CEO of Murky Water and his passion for building boats was born of his passion for paddling them.

“We spent every weekend up on the Ottawa,” he says. “We did paddling trips down to West Virginia, Colorado, Idaho and you always wanted to design something of your own that you thought would be better. That’s how I got into building.”

He built his first boat about 30 years ago. “I bought an old slalom boat, cut it up, shortened it, flattened it, made a deck for it, and then it was my own personal design.” Skrzypkowski then spent five years working at Upstream Kayaks in nearby Guelph, Ontario.

“I kept playing around with my own boats, as Upstream Kayaks grew, but then I realized there’s no market in producing your own boats,” he recalls. “You’re better off having well-known designers and just building their boats. I also thought it would be better to be smaller and more customized.”

So he left Upstream Kayaks and incorporated Murky Waters in 1994.

“I got permission from Jim Snyder to build his squirt boat design. Then I had other designers like Ian Thompson; he came up with the Departure when he was competing for the Canadian team. We did a lot of work with Corran Addison too when he first started up with Riot.”

“More recently we were approached by Jackson to build their competition boats; the carbon fiber All Star and the Rock Star. We basically pay them a royalty for every boat we build.”

Today Skrzypkowski is still working with the same basic precepts. Producing 40 to 70 boats per year, he runs the operation with his wife on their own property. Murky Water offers a seemingly limitless range of boat construction and designs. You can customize size, shape, graphics and materials. He hand crafts boats in his 2,500-square-foot shop using carbon, polyester or Kevlar. He’ll work with you to beef up the areas that need beefing up, or lighten the lay-up where it’s appropriate. But the custom attention to detail doesn’t mean it’ll be the most expensive boat you’ll ever buy.

“My aim has always been to build the lightest and strongest boats, but also the most affordable,” he says. “I think to keep the sport going, you have to make sure the products are affordable.”

As for the future of Murky Water Kayaks?

“This is going to be a deciding year,” says Skrzypkowski. “I’ve had some issues with health the past couple of years and I realized we’re actually turning away work because I physically can’t keep working seven days a week. I’d like to see the business go into younger minds, younger hands, that can keep the products going. I’m always canvassing; wanna learn a new trade? Especially if you’re a kayaker. You have an advantage because you understand the forces these boats go through.”

As for Ed, he obviously doesn’t get enough time on the water anymore, but he hopes to change that. “I haven’t kayaked seriously for about 15 years,” he says. “I got into building because I love kayaking. Before I do the ultimate mystery move into the ground, I’d like to get a few more years in the kayak and run a few rivers again.” —Colin Field

TITAN KAYAKS

ANTHONY YAP AND JACKIE HENNESSY

IF DREAMING up your own kayak design doesn’t sound like enough of a challenge, imagine also planning, engineering and building your own kayak manufacturing equipment; and then constructing a factory to put it in. And when that’s all done, producing boats, marketing them and running the entire business.

From high factory windows, tropical evening sunlight splashes across rows of candy-colored boats stacked neatly in racks. It’s after hours and the concrete floor of the Titan ‘Fantasy Factory’ is quiet; everyone has gone home except for owners Anthony Yap and Jackie Hennessy. In their office overlooking the factory, Jackie works on filling orders while Yap is in the research and design room—his favorite part of the building. Located on the edge of an industrial area in Kuala Lumpur, Malaysia, the Titan factory is only a 10-minute drive to the jungle, making the fantasy even more palpable.

This international power couple are the brains and brawn behind the evergrowing Titan Kayaks. Hennessy, an Irish paddler, met Yap while he was competing at the Penrith Whitewater Stadium in Australia.

“We’ve worked 60to 70-hour weeks for the past two years here in Malaysia setting up the factory,” says Hennessy. “Everything we have has gone into the company and it’s still just Anthony and I running the whole thing.” Yap’s name is usually the focus of attention and recognition when it comes to Titan because of his freestyle competition background, but he is quick to point the praises and credit toward his partner. “Jackie and I started it together,” he says, highlighting how the idea really came to fruition when they met.

With the new factory in action, Titan Kayaks are gaining momentum. “Our sales for the first three months in our new factory have doubled that of the last two years,” says Yap.

Titan sold their first boat in 2010, but Anthony began working on designs and prototypes years before that. The freestyle Genesis is by far their best seller, and can be found in outdoor stores around the world.

The company started production in Asia because Yap had family and connections in Malaysia. Titan Kayaks went from renting a small corner of another factory and third-party rotomolders to having their own custom-made equipment—including a new oven designed by Yap and created from scratch, specifically for making kayaks.

Hennessy designed the layout of the factory with sections for modeling, assembly, packaging and storage. Together, they have developed the factory production line, trained their staff and even developed their own plastic. “We can finally have full control of quality and production times. Now, there’s nothing really stopping us,” she says.

Their next step is setting up a home base in Canada. “The dream is to have the Fantasy Factory in Malaysia that can build all the cool toys,” says Yap, “and have a design hub in Canada on the Ottawa.”

“The most satisfying moment of this work is seeing someone paddle into an eddy in your boat,” says Yap.

Yap and Hennessy can be seen on the factory floor in tank tops, shorts and sandals, going from admin to management and designer to laborer. Yap flies from one production stand to the next on his longboard. They may have a fancy new factory, but at its core, it’s still the same athlete-based company. “We are kayakers making kayaks,” says Hennessy. —Carmen Kuntz

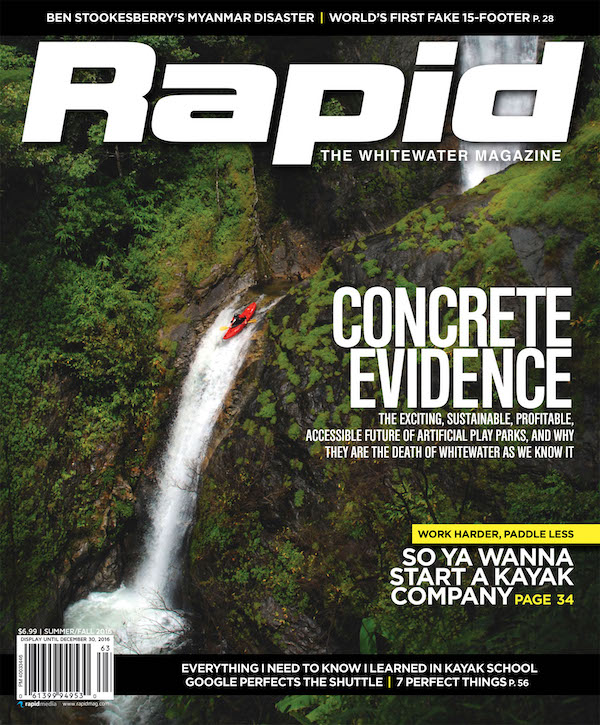

This article originally appeared in the Rapid Summer/Fall 2016 issue.

This article originally appeared in the Rapid Summer/Fall 2016 issue.

Subscribe to Paddling Magazine and get 25 years of digital magazine archives including our legacy titles: Rapid, Adventure Kayak and Canoeroots.