Once you filter out the PR spin, it can feel as if the technology of paddling is standing still. After all, many of the materials and methods we’ve used to produce boats, paddles and apparel have changed little in decades. That is, until recently. Whether due to fallout from supply chain woes, rising materials costs or legislation (see Bracing For The Coming PFAS Ban), the last couple of years have seen some exciting advances in paddlesports manufacturing. Here are just a few of the innovations we’re watching.

Five innovations that could change paddlesports forever

Shapewave | Tape Welding

From the chatter around trade show happy hours, you’d think a visionary SUP bro invented drop-stitch inflatables about a dozen years ago (was it Laird?). In fact, the high-pressure inflatable process dates all the way back to the 1950s, when Goodyear designed an inflatable airplane for the Pentagon. Their interest in drop stitching was the same as 21st-century paddleboarders—producing an inflatable that can hold a specific shape rather than puff up like a balloon—and it worked. Drop-stitch inflatables do indeed hold their shape, and that shape is flat.

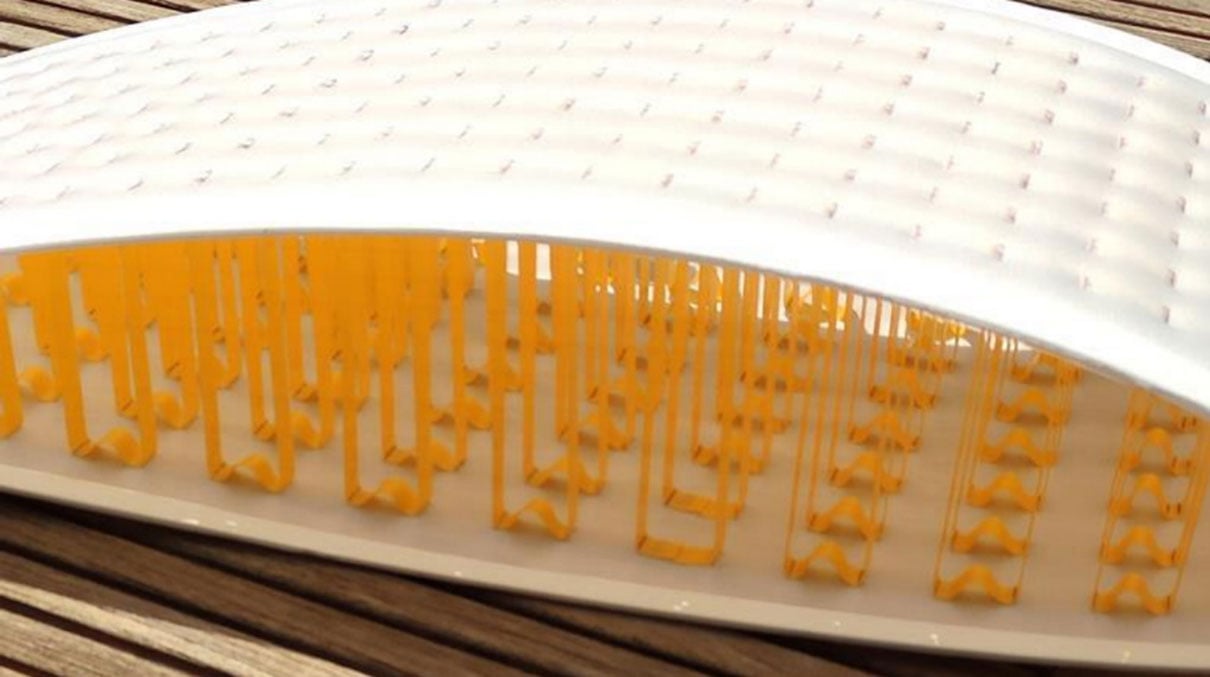

Dutch startup Shapewave is looking to shift the one-shape-fits-all paradigm with a new manufacturing process that could reimagine what we think is possible with inflatables. In place of the inner threads used in drop-stitch fabrics, Shapewave uses lengths of tape welded between the sheets of material, each of which can vary in length, attachment point and angle, allowing for complex shapes and curves. The secret sauce is Shapewave’s CAD-to-weld software, which creates a roadmap for their robotic Wavemaker01 welding machine. Translation: the closest thing we’ve seen yet to matching the rails of a hardboard.

Aqua Bound | Lam-Lok

Aqua Bound has long been known for its value-minded paddle designs. The Aerial series throws everything you think you know about the brand out with the river water, with an innovation that could revolutionize composite paddle blade design. Aqua Bound’s new Lam-Lok process wraps five meters of aramid stitching around the perimeter of each paddle blade, creating a durable mechanical bond between the composite layers. The idea is to prevent the painful-to-watch delamination of composite blades subjected to rocky rivers and shorelines. To measure the effectiveness of the armor stitching, Aqua Bound used a machine to test how much force it would take to rip apart two layers of fiberglass. Sheets of fiberglass bonded by resin separated under a mere 18 pounds of force. The Lam-Lok stitched fabric, laid out in the same manner as the Aerial blade, took 500 pounds to buckle.

Swift Canoe | Forged Carbon

Forged carbon debuted around 2010, when Lamborghini unveiled the show-stopping layup on a concept car at a Paris auto show. A decade and a change later, Swift Canoe & Kayak has brought the stylish space-age material to the grungy paddling scene.

The carbon fiber we’ve long used in paddling products is a woven fabric, laid up in a predetermined pattern. Forged carbon combines resin with shards of carbon under pressure to form a pattern completely unique from one inch to the next. Swift uses forged carbon as an outer laminate on their boats, combining an out-of-this-world finish with the strength of carbon fiber. Using a proprietary application method they can work out unique patterns and densities. Adding forged carbon marks a $1,500 USD upgrade to Swift’s Carbon Fusion layups. When it comes to moving away from the same old, same old, forged carbon brings a beautifully crafted dose of avant-garde to the paddling scene.

Esquif | T-Formex Lite

From the moment we lost our dearly departed Royalex, Esquif set out to create an equally indestructible alternative. The company’s T-Formex material, made of sandwiched foam and vinyl laminate sheets, has proven itself a worthy successor but Esquif never intended to stop there. With the unveiling of their latest canoe, the Huron 17, Esquif introduced us to their next material evolution, T-Formex Lite.

T-Formex is tough, but with that durability comes weight. T-Formex Lite provides a lighter alternative by varying the thickness and composition of the laminate sheets. That means optimizing the sheets for each model of canoe, using less material in some places and adding more where reinforcement is needed. T-Formex Lite will not be as stiff and durable as full-on T-Formex, but still promises to provide the reliable toughness the Esquif brand is built on. The weight-shaving difference is substantial. For example, an Esquif Canyon in T-Formex weighs 75 pounds while the same canoe in T-Formex Lite is almost 15 pounds lighter.

Melker of Sweden | Cork Kayak

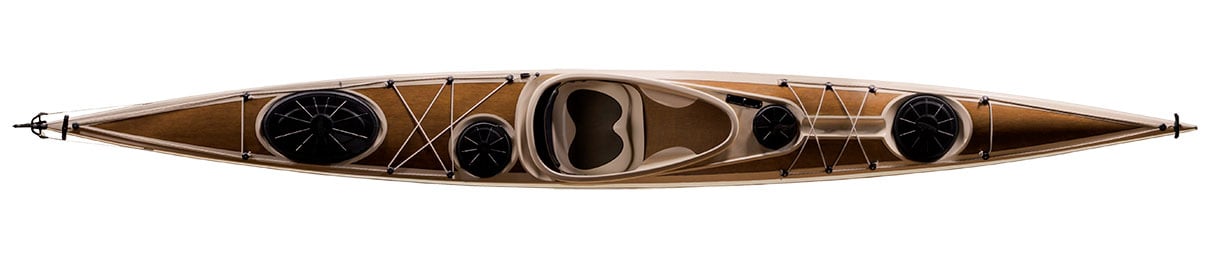

Every corner of the outdoor industry is wedded to petroleum products, and paddlesports is no exception. Whether plastic or composite, the boats we paddle start as a good-sized glob of oil. One manufacturer looking to change that is Melker of Sweden. Pelle Stafshede founded the company in 2015 with the goal of producing environmentally sustainable kayaks, which means moving away from the fossil-based polymers we’ve used since sealskin and driftwood went out of style.

Melker’s latest kayak design, the Värmdö, meets that ambitious goal thanks to a composite layup of cork and flax. Cork is a regenerative product, made from the bark of cork oaks, and it turns out it’s buoyant, lightweight, relatively impermeable and surprisingly durable. The toughness of resin-infused cork won’t shock anyone who’s shopped for flooring in the last decade, but kayaks? High-performance touring kayaks made from sheets of cork sandwiched between layers of flax may take a little getting used to, but Stafshede believes it’s just the sort of innovation paddling needs to kick its petrochemical addiction.

Feature photo: Paddling Magazine staff

This article was first published in the 2024 issue of Paddling Business.

This article was first published in the 2024 issue of Paddling Business.